Injection

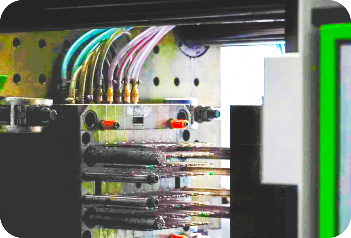

The injection molding process uses a Taiwanese high-speed injection molding machine, a five-axis automatic manipulator and a high-precision color master distribution machine to for its primary injection molding.

Quality Control

The injection molding QC performs the first inspection, trial assembly, patrol inspection, and sampling inspection on finished products. It has the ability to detect product tightness, pen tip slide and retraction force, anti-binding force, pen cap safe stomatal ventilation, plastic part color and other indicators, as well as the ability to provide feedback, follow-up and summarize quality abnormalities. Test equipment used: pen cap ventilation tester, tension meter, vernier caliper, airtightness tester and color difference meter.

Printing

The printing process uses automatic rotation of the product, automatic PP water treatment, 360-degree screen-brush and automatic processing of the disposable curing device for one-time molding.

Quality Control

The printing QC carries out the first article inspection, patrol inspection and sampling inspection on finished products according to the inspection criteria. It has the detection ability for such indicators as product appearance, printing effect, printing adhesion and printing durability, as well as the ability to provide feedback, follow-up and summarize any quality abnormalities. Test equipment used: 3M glue, vernier caliper, multifunctional friction tester.

Assembly

The automatic assembly process is composed of a high-sensitivity PLC integration and a high-precision imported divider, which can assists in the automatic product assembly process.

Quality Control

The assembly QC performs the first article inspection, patrol inspection, airtightness inspection and sampling inspection of finished products. It has the ability to detect ink color, weight, ink performance, writing performance, pulling force, anti-matching force, pen tip slide and retraction force, pen cap vent hole, inverted test, tightness and other indicators of the product, as well as the ability to provide feedback, follow up and summarize abnormal quality. Test equipment used: tension meter, electronic scale, vernier caliper and air tightness tester.

Package

The packaging workshop is composed of several manual assembly lines,and the workers manually order and packaging pens of various colors according to customer’s requirement. Experienced packaging line workers ensure the efficiency and precision of the packaging process.

Quality Control

Packaging QC conducts first-piece inspection, patrol inspection, and sampling inspection for finished products based on the inspection standards. Testing requirements include: product appearance and physical requirements, packaging material requirements, product color sorting, box marking requirements, packaging and sealing requirements, etc. Testing equipment used: metal detectors, barcode scanners, push-pull gauges, etc.