Manufacturing Process

Automatic

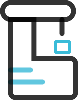

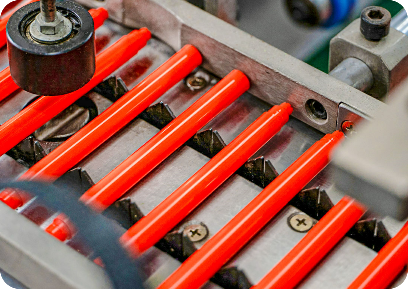

With a cumulative investment of 30 million yuan, Kaywin has introduced equipment (11 automatic assembly machines, 6 injection molding machines, 2 automatic screen printing machines, 2 card suction machines, etc.) to ensure the advancement of enterprise productivity, effectively ensuring the production efficiency of the entire company.

View MoreAbout Manufacturing

The manufature operates with an automated high-efficiency assembly line split into production groups. Kaywin plans to spend 5% of its annual sales on the development and procurement of new equipment to ensure that the company is always a leader in productivity within the industry.

Automatic Machine

Between 2015 and 2021, the company has invested more than 30 million yuan to purchase machinery and equipment, advancing the productivity of the industry.

millions PCS. per year

Product Categories

Ink Color

Personnels

World-class Technology

World-class Technology

Our leading technology makes the product safe, functional and environmentally friendly

View MoreQuality Standard

Quality Standard

All products go through a thorough inspection process to ensure excellent quality control.

View MoreProduction Capacity

Production Capacity

In 2021, we produced nearly 600 million watercolor pens, with gross earnings of more than 200 million yuan.

View More